Ashrae Cooling And Heating Load Calculation Manual Grp 158 Cm

HVAC Peak Load Calculation Methods – History and Comparisons HVAC Peak Load Calculation Methods – History and Comparisons by Bill Smith, president of Elite Software Copyright © 2011 This article discusses both commercial and residential HVAC (heating, ventilation and air conditioning) load calculation methods, and explains why results are often so different between methods. This article is intended to be understood by both the lay person and the HVAC professional.

To help the lay person, some definitions are in order. When most people hear the word 'load' they naturally think of a load of firewood they carry into the house, or a load of dirt in a dump truck, or maybe even a load held up by a beam or structural member. All of those loads are a 'weight' to be carried or supported in some way. Such loads are measured in pounds, kips, or kilograms, depending on the units involved. So what are heating and cooling loads? As pertains to heating and cooling equipment (an HVAC System), a load is a rate of heat transfer. Not a single quantity of heat, but an amount of heat that must be continually (at least for the worst case hour) removed or added to maintain the desired indoor temperature.

In the coldest time of winter, the peak heating load is the amount of heat that must be added over an hour’s time to keep the space warm. Imperial units system, this rate of heat transfer is in Btu’s per hour which is commonly abbreviated as Btuh. In the metric system the equivalent unit is a watt and one watt is equal to 3.41 Btuh.

Sep 21, 2012. Of ASHRAE TC 4.7, and was the chairman for ASHRAE's Performance. Peak Heating Load. Peak Cooling Load. • How did the methods evolve from 1900 to Present? • How did these methods treat the.

In the hottest time of summer, the peak cooling load is the amount of heat that must be removed in an hour to maintain a comfortable room temperature. Again, the cooling load unit is either Btuh or watts. What causes heating and cooling loads? A summer cooling load is a heat gain to the building. The sun provides all of the heat that comes in through the exterior of the building. And within the building itself, heat is generated by people, lights, equipment, and appliances. A winter heating load is a heat loss that is caused by loss of heat from the warm physical mass of the building to the cold air surrounding the building.

Heat is lost through the walls, windows, roof, and through cracks and crevices where cold air seeps into the building. It is important to know the peak heating and cooling loads on a building so that the HVAC equipment can be adequately sized. An undersized HVAC system will not be able to maintain the desired indoor temperatures. An oversized HVAC system will be inefficient, and struggle to maintain comfort conditions, particularly with humidity control during summer months.

Differences in HVAC Load Calculation Methods HVAC load calculations are most often done using computer programs, although some methods are still able to do be done by hand. Many people are often alarmed to learn that various computer programs and hand calculations can differ so widely on calculation results. After all, if each calculation is done with the same outside and inside temperatures, same building material types, areas and quantities of roofs, walls, glass, people, lights, equipment, etc., why should the results ever differ by more than a few percent? Complex Problem The physics involved in the transfer of heat and energy between buildings, occupants, and the environment is quite complex. The most current and best math models of this problem require significant input data and thousands of calculations in an iterative process. The calculations are so involved that researchers have been forced for years to create various simplified procedures that are doable by hand or within reasonable calculation time on a personal computer.

The cost of these simplifications from the theoretical best math models is accuracy. In theory, one generalized HVAC load calculation procedure should work for all types of buildings. There would be no need for separate procedures for different types of structures, either residential or commercial in nature. In fact, such a generalized method has been developed in recent years, and it is called the Heat Balance (HB) method. And it can be used on buildings of all types.

However, there are various issues with HB, discussed later, that make it less popular to use for peak load calculations than many of the less sophisticated methods that are designed only for residential or commercial buildings. Early HVAC researchers learned that simplifications in calculation methods could be made if generalizations about the subject buildings could be assumed. This led to HVAC load calculation methods that were designed only for residential or commercial buildings. Residential buildings, in particular, were believed to be more simple in construction and usage.

Home owners were traditionally considered to be less demanding than commercial building owners, especially since commercial buildings usually cost far more than houses. For these reasons, residential HVAC load calculations procedures have traditionally been much less sophisticated than commercial procedures. Besides separate methods for commercial and residential buildings, another major factor that has influenced load calculation methods over the years is the use of computers. Before personal computers were widely available, simple procedures were even more important to have, as doing calculations by hand is slow and tedious. Many procedures to this day still have simplifications for the reason of making hand calculations possible.

Commercial Load Calculation Methods In the calculation of commercial building peak heating and cooling loads, many methods have been developed over the years. ASHRAE has TETD (Total Equivalent Temperature Difference), CLTD (Cooling Load Temperature Difference), TFM (Transfer Function Method), HB (Heat Balance) and RTS (Radiant Time Series). ACCA has the Manual N method, an updated variation of the ASHRAE CLTD method. There are two other calculation methods primarily used for 8,760 hour-by-hour annual energy analysis that are also sometimes used for peak load calculations. All the various computer programs such as EnergyPro, eQUEST, EnergyGauge USA, REM/Rate, and others that are based on the DOE (Department of Energy) 2.1e program use what is known as a weighting factor (WF) method. The most current and sophisticated energy analysis program was developed by the U. Torrent Microsoft Office 2010 Proofing Tools. S. Government, and is called EnergyPlus.

It uses the Heat Balance (HB) method. In general, the energy analysis methods, WF and HB, are more sophisticated than most of the methods used just for peak heating and cooling loads, such as TETD and CLTD. Although the WF and HB methods were primarily intended for 8,760 hourly analysis, they can also find peak heating and cooling loads during the course of a year for all types of buildings, both commercial and residential. Residential Load Calculation Methods ACCA has a residential load calculation procedure called Manual J.

It has been updated over the years, and is now on its eighth edition. As ACCA upgrades its procedures, it does not create new names for the procedures. The name stays as Manual J and only the edition number changes. The current ACCA residential method is commonly called MJ8.

ASHRAE has offered residential load calculation procedures for many years as well. Unlike ACCA, ASHRAE creates a new name for a procedure when it undergoes a major change or replaces an earlier procedure. In 1985, ASHRAE used the Design Equivalent Temperature Difference (DETD) approach, and from 1989 through 2001 the procedures were called the residential CLTD method. In 2005, ASHRAE introduced both the Residential Load Factor (RLF) method and the Residential Heat Balance (RHB) method.

While ASHRAE introduced two new residential methods in 2005, the ASHRAE Handbook of Fundamentals (HOF) in 2005 and 2009 supplies tables and shows an example calculation using only the RLF method. In fact, the ASHRAE 2009 HOF states that RHB is a research-oriented implementation of the HB method and that it is expected that RHB will one day be incorporated into third-party software. As of the time of this writing in April 2011, there is no software available that implements the ASHRAE RHB method.

As explained above for the commercial procedures, the sophisticated WF (weighting factor) and HB (Heat Balance) methods used in several building energy analysis programs can also be used for calculating peak loads on residential buildings. Result Differences Once you realize that significant simplifications have been made in all the popular HVAC load calculation methods, it is easy to understand why there will often be significant differences in results from those procedures. Over time, these various methods have been applied to the same buildings, with results sometimes differing by as much as 40%.

Inevitably, the question becomes, which results are the most accurate? The greatest difference between calculation methods always happens when one method is misapplied. For example, entering a complex building like a hospital as equally as possible into an ASHRAE RTS computer program and into an ACCA MJ8 program will yield hugely different results, with the RTS loads being much higher. This is easily understandable, as the RTS program calculates hour by hour, and the MJ8 program uses simplified weighted average factors for roof and wall loads. In such an example, there is no problem at all in acknowledging which results are more accurate. Let's consider a more realistic case where the ACCA MJ8 procedures are used on the same house as the ASHRAE RLF procedures. In this case you have two residential specific procedures used appropriately on their intended type of building, a house.

Additionally, both procedures are based primarily on the use of lookup tables such that the calculations are still doable by hand. Will the results from these procedures differ? Assuming all areas, temperatures and other data have been entered as equally as possible, result differences between MJ8 and RLF will vary much less than between disparate methods such as RTS and RLF. However, loads will still tend to be higher with MJ8 because it has hourly load factors on glass (but not on roofs and walls), while the RLF method uses averaged load factors (no unique hourly load factors) for all exterior building surfaces, including glass.

The above two examples illustrate relatively straight forward reasons for differences in results between methods. Some load calculation procedures have very obvious differences in methods.

The method using the more advanced technique is usually more accurate. More Reasons for Result Differences There are many difficulties in trying to compare HVAC load calculation methods. Assuming that all quantities of load components (roof, wall, and glass areas, number of people, lights, equipment, etc.) are made equal, and that all indoor and outdoor design temperatures are equal, there is still a great deal of variability for many other input items. For example, one method like the CLTD procedure offers only seven types of walls in categories A-G. You can assign what ever U-factor you like to a wall, but every wall in the world must fall into one of the seven categories that is primarily distinguished by the thermal mass of the wall.

Other methods like HB, allow for smooth and infinite variations of wall types with different thermal mass. When using the CLTD method, many real world walls could be legitimately selected as either of two CLTD wall type categories, as they are not clearly in one category or another. The same thing happens for roofs under the CLTD method, where only 13 roof types are provided. The MJ8 method is derived from the CLTD method, and thus has similar limitations on the roof and wall categories. The ASHRAE RLF method has even more limited selections for roofs and walls. These finite 'type' selections cause abrupt differences in loads calculated for a roof or wall of the same U-factor and same indoor-outdoor temperature differences. The more simple the load calculation method, the fewer the 'type' categories provided for roofs and walls.

There is also a chance for great disparity on glass loads because there is both a transmission and solar component to deal with. Many of the tabular based methods make great simplifications, especially with the solar gains. Even fairly sophisticated methods can show significant differences on glass solar gains. More than actual calculation method differences, the most common reasons for differences in load calculation reports from different computer programs on the same building are from quantity discrepancies. Sometimes there are just outright mistakes on roof, wall, and glass areas. Same goes for the count on people, lights, and equipment. Confusion over how to handle fresh air in terms of ventilation or infiltration causes significant differences as well.

Even when expert load calculation software users compare results on the same building there will be differences. As discussed above, there are judgment calls on building material type selections that experts can disagree on, and yet can defend their selections with equal validity. Which Method is Most Accurate?

The first question many people often ask is, which HVAC load calculation method is most accurate? There is unanimous agreement that the Heat Balance method most accurately reflects the true physics involved in heat gains and losses to buildings. And yet at this time, there is no dedicated residential or commercial peak load computer program that uses the HB method. Only the EnergyPlus software uses the Heat Balance method and EnergyPlus is used primarily for building energy analysis, not peak load analysis. There are two main reasons HB is not yet widely used in HVAC peak load calculation software. First, there is the complexity of the HB method.

A designer must be prepared to enter more data and more details for all the load components. This is time consuming, and requires more thought and engineering judgment. Second, and most importantly, is that the HB procedures 'blend' all the component loads (roofs wall, glass, etc.) together during the calculation process. At the end of the calculation process, only a single number as a gain or loss in heat results. There is no way to see how much effect there was from the windows or the people or the lights, etc.

Everything is blended, or rather 'balanced,' before a final result is obtained. Since so many economic decisions are made as to whether to use certain building materials or not, HVAC designers often find it imperative to be able to review component details of an HVAC load calculation.

All non-HB load calculation methods preserve this ability. The Radiant Time Series (RTS) method is the closest in accuracy to the HB method while still providing component load details. At this point in time, the RTS method is only available as an ASHRAE sponsored method primarily for use on commercial buildings. The RTS method is robust enough that, like the HB method, it could theoretically be used on both commercial and residential buildings. However, the RTS method relies heavily on the conduction time series (CTS) concept, which helps to model the time lag of heat transfer for various building materials. Very light poorly insulated materials can transfer all the heat from a test heat 'pulse' in as few as four hours, whereas well insulated heavy materials might need a full 24 hours to transfer all the heat from a test pulse. The CTS series for a material describes that reaction to heat.

ASHRAE provides about 35 suggested CTS values for mostly commercial building material combinations. For the RTS method to be used properly for residential peak load calculations, CTS values would need to be generated for more residential roof and wall materials, and this has not yet been done.

If the HB method is the acknowledged most accurate method, but has the drawbacks mentioned above that make it so rarely used for peak load calculations, what then are the most accurate practical peak load calculations methods available today? For commercial buildings, it is this writer’s opinion that the ASHRAE RTS method is the best overall method, as high accuracy is obtained while also preserving the details of load contributions from all the various internal and external components. Good results can be obtained from older and simpler methods such as the ASHRAE CLTD and TFM methods, as well as the ACCA Manual N commercial method. So stating a preference for the RTS method is in no way saying that the other methods should be avoided. An experienced designer using those methods may very likely calculate more accurate results with those methods than a novice using the RTS method.

For residential buildings, the ACCA Manual J 8th edition method is the best overall method. It definitely lacks in sophistication compared to the ASHRAE HB and RTS methods, but those methods are not fully developed for use on residential buildings.

The ACCA Manual J method has been honed for many years on residential structures, and has a very successful track record. Comparison of Residential Methods It is not uncommon for individual HVAC designers to have a favorite HVAC load calculation method that they use on all buildings. Consulting engineers often like using ASHRAE commercial methods on all their projects, both residential and commercial. HVAC contractors, on the other hand, often like to use the ACCA MJ8 method on all their projects both commercial and residential.

Both types of HVAC professionals generally have a long history with their preferred method and know how to adjust the method for various types of projects. I am going to go out on a limb and state some broad generalizations that are based purely on my own anecdotal experiences and what I have heard from thousands of HVAC designers served by Elite Software for over 31 years. It is important to understand that these generalizations have no scientific basis and could be completely wrong. Skilled users of any load calculation method are able to adjust inputs in subtle ways that can steer results high or low. All of my observations are based on a knowledgeable user entering data as equally as possible, and with no attempt to influence the results. Unlike with commercial methods, where there is more competition amongst the methods, the Manual J method has been extremely dominant over the years with its number of users versus anything else. In my opinion, the ACCA MJ8 method produces the most accurate equipment sizing information for houses, even though it uses one of the more simplistic methods (a simplified variation of CLTD).

With many successful users of Manual J over many years, I have developed a high confidence in Manual J. Thus, the current MJ8 method is what I will compare all other residential methods to.

The feedback I have from the very few people who have done ASHRAE RLF comparisons with MJ8, indicates reasonable closeness of results, with RLF usually being slightly lower. In the case of peak residential load calculations involving a DOE2 based program on a house and using the weighting factor method, the MJ8 method will tend to be 15-20% higher. The same thing happens when compared with the Heat Balance method. MJ8 tends to be higher in the same range. When MJ8 is compared to the ASHRAE CLTD or RTS method on a house, those two commercial methods tend to be 15-25% higher than MJ8. Consulting engineers are often conflicted about this. They know the ASHRAE commercial methods have built-in assumptions for commercial buildings, but they wonder whether that matters much.

Many engineers prefer using the higher loads from the ASHRAE commercial methods and believe there is no problem with using those methods on houses. As a final note on residential methods, a lot of questions come up about how MJ8 compares to MJ7. When MJ8 was first released in 2003, many MJ8 calculations were coming out higher than MJ7 for the same house. It turned out that the way users were interpreting duct inputs in MJ8 caused those loads to go much higher than MJ7.

Addenda C of MJ8 added additional duct inputs that tended to reduce the duct heat gains. After further testing, it was found that MJ8 and MJ7 tended to agree within plus or minus 5%, with MJ8 sometimes being lower and higher than MJ7. While MJ8 results compared closely with MJ7 results on equivalent building materials, new materials is where MJ8 surpassed MJ7. Tomtom Maps Central And Eastern Europe Download Movies.

MJ8 includes hundreds of more roof, wall, and glass material types than MJ7. With some modern material types, like insulated concrete forms, MJ7 simply can’t calculate well for those, while MJ8 can. Besides material issues, infiltration and duct gains and losses were made more accurate in MJ8 as well. So while overall results on projects that both methods can address aren't huge, MJ8 was still a big improvement over MJ7. Comparison of Commercial Methods In the comparison of commercial load calculation methods, there is more controversy over which method is best than there is with residential methods.

The three most popular commercial methods are ASHRAE CLTD, TFM, and RTS. ACCA has a commercial method called Manual N, which is a variation of the CLTD method, so all comments concerning the ASHRAE CLTD method are applicable to the ACCA Manual N method. The HB method is not used in any dedicated commercial peak load calculation program at this time, but it is used in the EnergyPlus energy analysis program, which is sometimes used by a very small percentage of designers as a peak loads program.

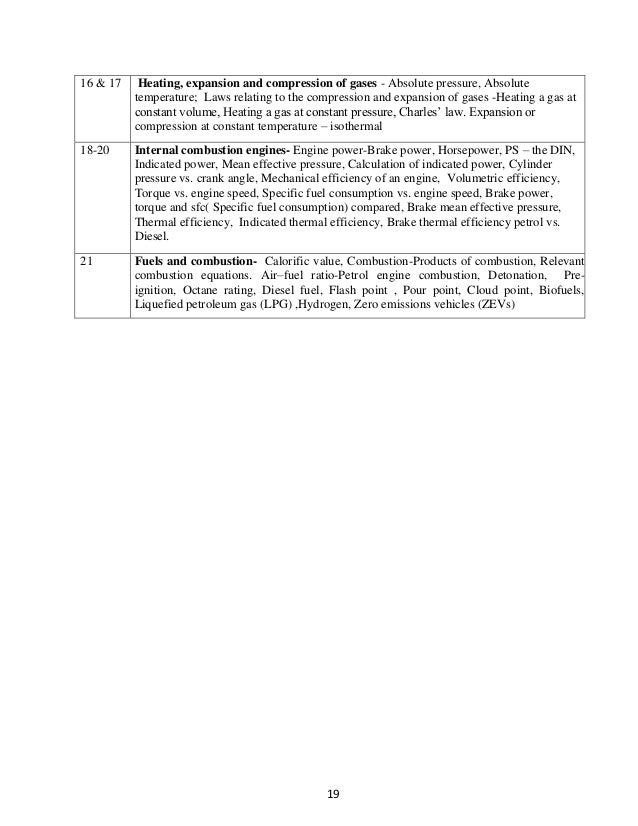

The WF method used in all the DOE2 derivative programs is also used by a small percentage of designers for the calculation of peak loads The ASHRAE CLTD method is the oldest of the current popular commercial methods, and was first introduced back in the 1977 HOF. It was further explained in the 1979 ASHRAE GRP-158 manual. It is actually a simplification of the TFM method much in the same way that RTS is a simplification of the HB method.

The basis for the TFM method was first published in the 1972 ASHRAE HOF. However, the TFM method is more math intensive than CLTD, so it took much longer to develop into useable a form for HVAC designers.

Being a simplified method derived from TFM and able to be tabularized, the CLTD method was able to be used by designers with slide rules, early calculators, and pencil and paper. It was also simple enough that it could be automated on very early small 64k memory personal computers (called microcomputers in those days).

Elite Software was the first to implement CLTD on personal computers back in 1979. In the mid 90’s, personal computers gained enough memory and computational capability that the TFM method was able to be implemented. The CLTD method enjoyed popularity right from 1977, and if it was derived from TFM, shouldn't a true TFM method become more popular than CLTD?

In my opinion, the TFM method did not become more popular than the CLTD method. Carrier exclusively adopted TFM into its software, while Trane offered it as an option along with CLTD and other methods. Elite Software never adopted the TFM method, as there were a lot of discrepancies with CLTD results on glass solar loads, especially with the south orientation. Some people argued that TFM, being more math oriented, should be trusted over CLTD in those cases, but many engineers believed that the reduced TFM solar loads, sometimes as much as 40% lower than CLTD, were not believable. This controversy was large enough that Elite Software never implemented the TFM method into its software. Besides questions about glass solar load accuracy, another reason so many HVAC designers continued to prefer the CLTD method was that it was manually verifiable.

A designer was still able to verify by hand the calculations of any computer program that used the CLTD method. With the TFM method, the calculations were so involved that there was no practical way for a designer to manually verify them.

Results from a computer program using the TFM method were essentially 'black box' results that had to be accepted on faith alone. As time passed, HVAC designers became more comfortable accepting results that could not be manually verified. This helped increase the popularity of TFM, but also opened the door for accepting other improved methods that could not be easily hand verified. In the 2001 ASHRAE HOF, the HB and RTS methods were introduced. As mentioned previously, the HB method is theoretically the most accurate method of peak load calculations. Elite Software studied these methods and learned why two methods were introduced simultaneously, something ASHRAE had never done before.

HB was developed for maximum accuracy while RTS was derived from HB to preserve component load contributions in the final results that the HB method does not preserve. In discussion with various developers of the HB and RTS methods, Elite Software was able to determine that RTS was preferred by most consulting engineers. And just as important, it was discovered that glass load results from RTS did not differ as much from CLTD as TFM differed from CLTD. Thus, anecdotal confidence in the accuracy of the RTS results was high, and Elite Software became the first software company to implement the RTS method in commercially available software in 2004. In my observations over the years and across a broad spectrum of projects and locations, the CLTD method has tended to calculate overall higher than TFM, typically about 10-15%.

As mentioned before, specific glass solar calculations could be higher by as much as 40%. The CLTD and RTS methods compare fairly closely, and either method can be plus or minus 5-10% of each other. This close agreement happens when making close matches of CLTD material types with RTS material types, i.e., first selecting a CLTD building material, and then matching it to an RTS material.

If you go in the other direction from RTS to CLTD, RTS allows so much variation and sensitivity on material variations that you can’t always get a good match with a CLTD material. A major benefit of RTS over CLTD is the provision for absorptance, emittance, Delta R, and H-outside coefficients.

The effects of these factors are built into the CLTD tables and are not specific user inputs as they are with RTS. When compared to peak loads obtained from the DOE2 WF method and the EnergyPlus HB method, it always seems to me that those methods calculate lower than CLTD, TFM, and RTS, usually in the range of 10-25% lower. This is very easy to explain for winter heating loads. The energy analysis programs when used as peak load programs always take credit for any solar gains, people, lighting and equipment loads to help offset winter heat losses. The specific peak load methods are more conservative and do not give credit for any offsetting loads to winter heat losses. To me, the conservative approach is justifiable, as the peak winter heat loss can easily occur in the dark of night with no one at home and no lighting or equipment operating.

Why the energy programs using WF and HB methods tend to always calculate low on peak cooling loads compared to MJ8, CLTD, TFM, and RTS is harder to understand. One reason that it is hard to analyze is that the energy programs don’t give a good break out of the individual component loads. So you can’t compare differences in the roof, wall, and glass loads at the worst case outdoor design conditions. Another reason I believe there are frequent differences in the peak loads of energy programs is that it is harder for a designer to control what the extreme upper and lower outside temperatures are. Many designers don’t make sure the outside design temps are equal when comparing peak loads from an energy program to a dedicated peak loads program. The energy programs tend to use less extreme outdoor temperatures and this reduces the peak loads they calculate. Whatever the reasons for these differences, many designers do not trust sizing HVAC equipment based on the peak heating and cooling loads obtained from software primarily developed for building energy analysis.

I agree with that concern, as there is a high risk of under sizing HVAC equipment when it is sized based off the peak load calculations from various energy analysis programs. This concern is valid for equipment sizing in both residential and commercial applications. In my opinion, the ASHRAE RTS method is the best overall commercial peak load calculation method available today, as it provides both high accuracy and component load contribution (roof, wall, glass, etc.) reporting. Perhaps someone will develop an approach in the future that allows the HB method to retain component loads in the final results.

Perhaps designers may evolve to where component load details are not so important to them. Perhaps a completely new theory will be developed that is more accurate than HB and with preservation of component loads. But until then, I believe RTS is the best overall commercial HVAC peak load calculation method available today. Summary In the residential world, the ACCA MJ8 procedures remain the most popular residential sizing method. The MJ8 procedures are not technically advanced compared to the dedicated commercial methods such as TFM and RTS. And MJ8 is certainly not as advanced as the methods able to do both residential and commercial peak loads and energy analysis such as the WF and HB methods.

But what MJ8 has going for it is years of dedicated specific residential structure heat transfer analysis. This has allowed the development of hundreds of load factor tables that represent very well what happens in peak HVAC loads on residential structures.

As ACCA continues to refine its procedures, I think the Manual J method will see big changes in the coming years as it catches up on calculation theory with the more advanced commercial and energy analysis methods. As mentioned before, the ASHRAE RTS method is a great method in that it employs only a small compromise from the HB method in order to maintain component load contributions. I think the RTS method has a very long future, with only small refinements needed.

About the Author: is the president, owner, and founder of Elite Software. Smith wrote the first commercially available load calculation program using ASHRAE CLTD procedures in 1979. Elite Software was the first company to sell an ACCA Manual J program based on the 6th edition in 1984. Smith invites your comments on this article, and will continue to update it as more developments occur.

Smith welcomes your email about this article.